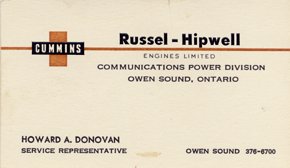

| Howard Donovan An employee of Russel Brothers Ltd. and Russel Hipwell Engines Ltd., 1950-1966

ENLARGE TO 1024 PIXELS

Howard writes: "This passport photo was taken over 40 years ago when I was chosen as backup person for a Cummins Diesel Generator set

install in Japan." Note Japanese stamps. |

|

| |

Howard was born and raised on a farm in Sullivan Township. He served overseas during WWII from 1942 to 1946. After the war, Howard obtained his motor vehicle mechanics license in 1950 and soon after took a position with Russel Brothers as a Fitter's Helper. Within a year he was transfered to Russel Hipwell Engines where his mechanical talents could be better utilized.

Howard's shop duties included assembly of:

- Hydraulic power steering for boats

- Cummins diesel generator sets used as standby emergency power in hospitals, telephone and telegraph systems, etc.

- Retro-fitting highway trucks from gasoline engines to diesel

|

Out of shop duties took Howard to numerous locations across Canada from Grand Falls, Newfoundland to Port Hardy, Vancouver Island installing Russel equipment, including the following highlights:

1955: When the Maid of the Mist III was transported into the Niagara Gorge in 4 sections, Howard was on site to connect the hydraulic steering system

1958: Howard visited Grand Falls, Newfoundland to re-power several construction gravel trucks from gas engines to Cummins Diesel engines.

1959: Russel Brothers was awarded a contract to build 3 landing craft to be used on the Atlantic Coast, delivering needed supplies from larger vessels to Inuit villages and other outposts. The landing craft were launched at Port Credit and Howard sailed to Montreal as the engineer. The boats were delayed for 4 days in Prescott as a result of the festivities associated with the opening of the St. Lawrence Seaway in July 1959.

1961: Howard spent 5 months in Labrador installing no-break generator sets at 3 USAF bases (Goose Bay, Hopedale, & Saglek) in conjunction with the Ballistic Missile Early Warning System. The Cummins generator sets provided uninterrupted power in the event of a power outage through the use of a 1-ton flywheel that was continuously spinning.

These were interesting and challenging years which Howard thoroughly enjoyed.

Howard ceased employment with Russel-Hipwell shortly after the company relocated to Toronto to provide better service to diesel traffic on Highway 401 (it was simply inefficient for trucks to drive to Owen Sound for maintenance).

After leaving Russel's, Howard spent 21 years at the General and Marine Hospital in Owen Sound, retiring as Chief Engineer in 1987.

MR. DONOVAN NOTES:

1. Maid of the Mist Delivery and Re-assembly 1955 (Howard witnessed and participated in this procedure)...

Russel Brothers contracted John McArthur Construction of Owen Sound to deliver the four sections of the Maid of the Mist III to the dock in the Niagara Gorge.

The four sections were placed on flatbed trailers in the RBL yard, then transported by road to Niagara Falls. Upon arrival in Niagara Falls, the flatbed trailer was backed into a position where a narrow, winding road led into the gorge. The tractor which had been pulling the trailer was then disconnected and turned around so that a front-end winch on the tractor could be attached to the front of the trailer. The cargo was then slowly lowered into the gorge along the narrow, winding road. Manouvering the hairpin bends of the road down to the dock was accomplished by means of a "come-along", which was fastened to a tree or other stationary object and could change the direction of the trailer.

Cranes were used to remove boat sections from the flatbed trailer, placing them on timbers for re-assembly. Signs were erected to warn the many spectators witnessing the procedure that "electric welding flash could be harmful to the naked eye".

2. 1958 Truck Retrofit - Grand Falls, Newfoundland

During WWII, a fleet of approximately 8 gravel trucks was deployed by the USAF for the construction of landing strips at USAF bases in Newfoundland. After the war, the trucks were purchased by Goodyear Construction of Grand Falls. These trucks had originally been equipped with Hercules Gas engines and Goodyear Construction found them very expensive to operate. Most trucks prior to the 1950's were equipped with gasoline engines.

The gasoline engines were removed from the fleet and replaced with Cummins "J-series" engines. This retrofit resulted in huge savings for Goodyear Construction, with the trucks achieving approximately 8 miles per gallon of diesel versus approximately 1 mile per gallon of gasoline. Diesel engines in trucks became the norm during the 1950's due to their reduced operating costs.

3. 1961 No Break Electrical Stand-By System - BMEWS (Ballistic Missile Early Warning System)

The large flywheels were moulded and machined by Kennedy's foundry in Owen Sound, and were balanced by Russel Hipwell Engines Ltd.

|